Photo Gallery

Gear Department

Small chain sprocket machined from on hand, alloy, forged stock in the inspection department.

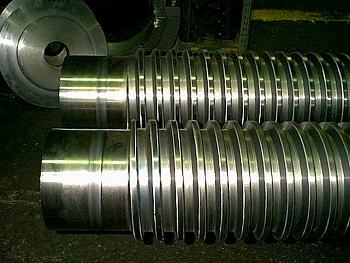

Unique buttress thread, screw

downs for large steel mill.

Cutting internal splines on a Fellows Gear Shaper at South Side Machine Works Inc.

Cutting large spur gear on our 160H Gould and Eberhardt Gear Hobber at South Side.

These large gears were cut at South Side Machine Works Inc. and then Blanchard ground.

Large shaft with three splines and a thrust collar, polished and ready for shipment at South Side Machine Works Inc..

Another large spur pinion being finished cut at South Side Machine Works Inc..

Bevel pinion gear being cut on South Sides' Gleason mill.

Custom made gear and sprocket assembly. Pieces were fabricated individually and then assembled with bearings.

Splines being cut on South Sides' Barber-Colman machine.

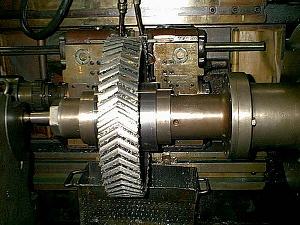

Cutting double helical pinion gear on a Sykes Herringbone Gear Machine at South Side Machine Works Inc..

Large double splined shaft ready for shipment.

Picture of double helix gears being cut on one of our Sunderland gear shapers.

Picture of true Herringbone gear being cut on our Ferrel gear shaper.

What ever your application, South Side Machine Works Inc. and Fulton Iron International can fill the bill. Our Metric gear cutting department is stocked with a complete set of hobs to get the job done quickly and at a competitive price.